The Rayleigh-Ohnesorge Jet Extensional Rheometer (ROJER) was developed in a project I led with Gareth McKinley at MIT, whilst I was still working for ICI and AkzoNobel.

We developed it to address the unanswered questions about the behaviour in extensional flows, of complex multi-component microstructured fluids - see page on extensional viscosity and spraying.

The ROJER considerably extends the range of strain rate and minimum relaxation time, when compared to CaBER and DoSER, which makes it exceedingly useful for characterising formulation rheology for spraying - especially, for engineering the very subtle formulation tweaking needed for spray droplet size control. However, the instrument was delicate and complex to use - making it only deployable in a handful of academic labs, and for measurements in-house at THCi in support of commercial client projects.

Motivated by that work for industrial clients, for a number of years we were developing a version for industrial laboratory use, as a back-burner project with Nik Kapur at The University of Leeds. see Greiciunas et al 2017 Design of a ROJER, JoR, 61, 3, 467 (and open access on whiterose.ac.uk).

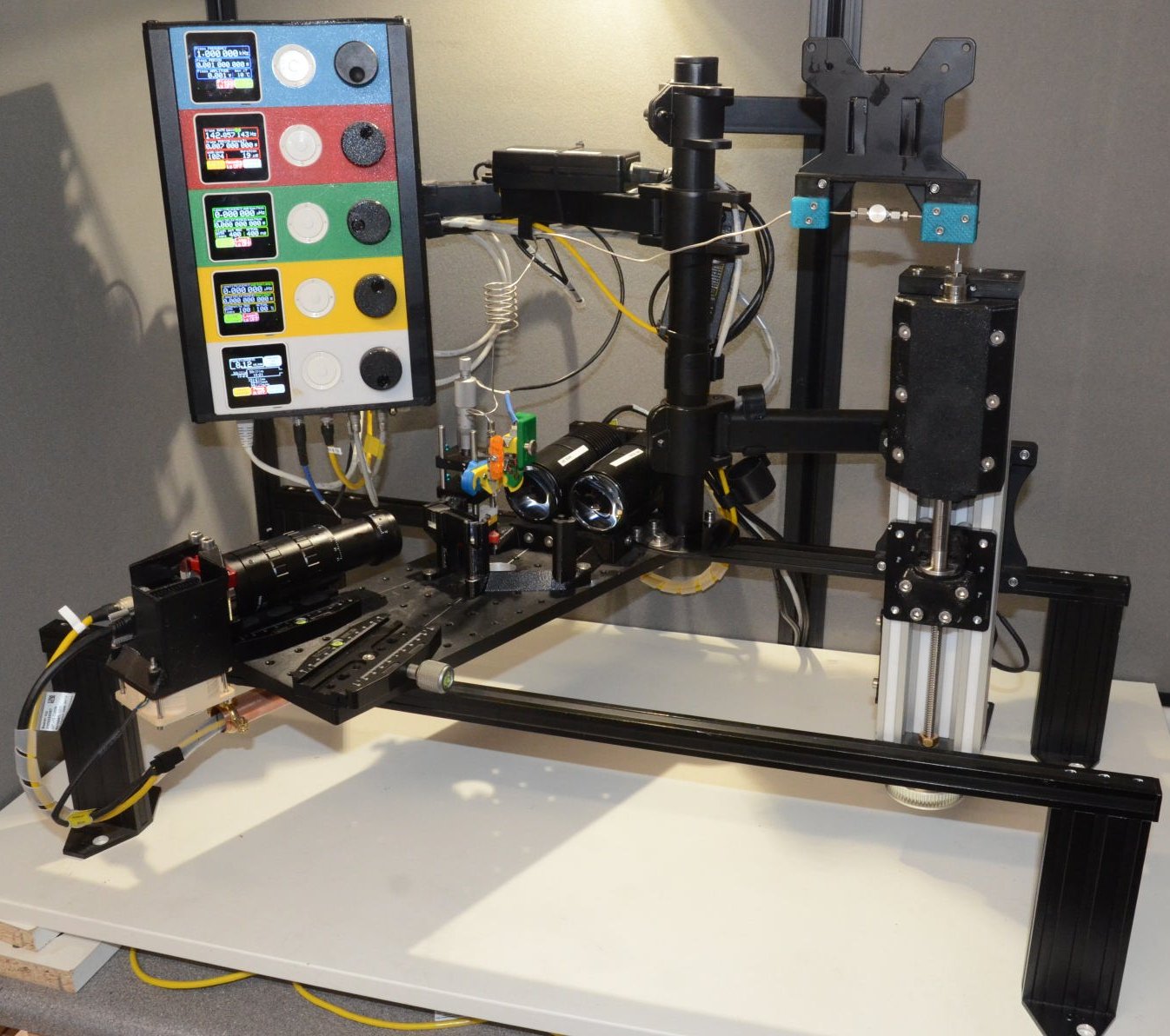

We now have a version of the ROJER available for commercial purchase, which has been engineered for industrial laboratory use. A key feature is simultaneous orthogonal views of the jet. We dub this ROJER-X denoting both an eXtended method and the crossed views on the jet. Initially conceived primarily to address the numerous usability challenges that have limited the adoption of ROJER, especially in industrial research laboratories, we have additionally found exciting enhancement in capability, with the instrument specified to measure down to sub-microsecond extensional relaxation times. Whereas conventional capillary thinning techniques (CaBER, DoSER) observe a single fluid bridge, ROJER measures thousands of bridges a second, for many minutes of fluid flow from a syringe. This radically improves the statistics of diameter-decay curve fitting, and fluid sampling of real commercial formulations inhomogeneous on a single liquid bridge lengthscale. Such jets won’t remain stable in frame and focus for minutes: ROJER-X makes it practical to reposition and refocus on-the-fly: obtaining a time history of measured rheological parameters quantifying non-homogeneity. The two images of the same bridge can be synchronised, or be in fixed or phase delay from each other and/or the jet resonance driving frequency. This permits (a) cross-checking that it is truly a rheometric flow in 3D and remains in Rayleigh resonance, and of the image-analysis-derived rheological parameters; (b) a direct measure of jet speed, independent from a pump flowrate derivation; (c) a "coarse and fine" delay, simultaneous construction of the filament thinning curve, with more rapid acquisition and less fluid consumption.

Since all these operating modes are programmatically controlled through the custom controller, with streamed image acquisition, it also has the potential for real-time analysis (a unique capability for extensional rheometers), and eventually automatic setup and adjustment of parameters. These features are in active development.